Effluent Treatment Plant

Introduction to Effluent Treatment Plant

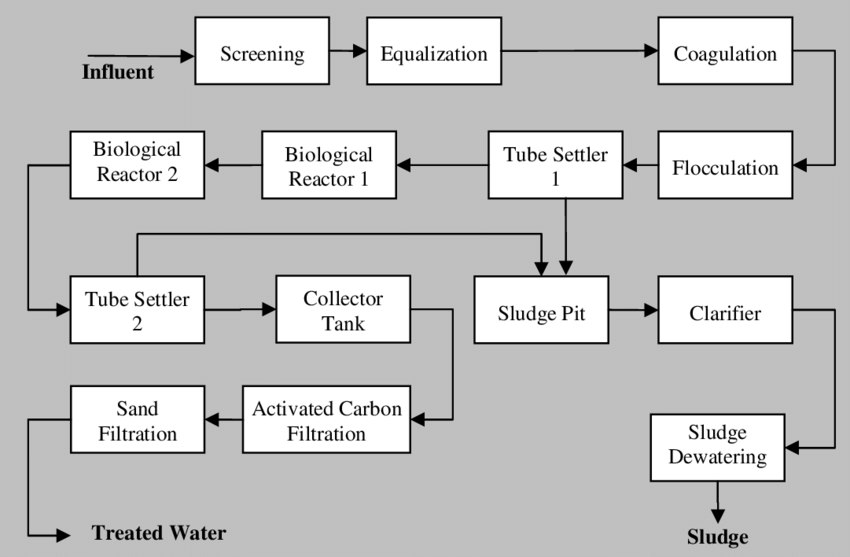

The process design used for safe reuse or disposal of Industrial Waste Water is called ETP (Effluent Treatment Plant)

• Influent: Industrial waste water which is untreated

• Effluent: Industrial waste water which is treated

• Sludge: Solid part separated from wastewater through Effluent Treatment plant.

Effluent: The word effluent today has a broad definition that can be simply understood as any water or gas that is released during a manufacturing, processing, or other process from its main stream or by product streams and may have the potential to harm the environment through air, water, or land pollution due to the presence of in organics, biological residues, chemicals, or other substances in the output water.

Treatment Levels & Mechanisms of ETP

Treatment levels:

- Preliminary

- Primary

- Secondary

- Tertiary (or advanced)

Treatment mechanisms:

- Physical

- Chemical

- Biological

Preliminary Treatment level

The physical separation of significant contaminants, such cloth, cardboard, paper, plastic, etc.

Common physical unit operations at the outset include:

Screening: A screen with consistently sized openings is used to remove material.

Large solids like cloth and plastics are often used up to a maximum of 10 mm.

Sedimentation is a physical procedure that uses gravity to clean water. Removing the suspended particles from the water.

Clarification: Used to distinguish between liquids and solids.

Primary Treatment Level

Particle removal from the water and the settling area, including suspended

both solids and organic compounds.

Methods: At this stage of treatment, both chemical and physical methods are used.

Operations of Chemical Units

Physical actions can be used in combination with biological treatment techniques and are frequently integrated with chemical unit processes. In order to enhance the effluent’s quality, chemicals are added throughout chemical operations.

Examples include regulating pH, coagulation, chemical precipitation, and oxidation.

pH Regulation

To balance the pH during the treatment procedure in order to create wastewater.

For acidic rubbish, use NaOH and Na2CO3 (low pH)(OH)2 Ca or Ca (CO3).

H2SO4 and HCl for alkali wastes (high pH).

Chemical Coagulation and Flocculation:

The process of coagulation involves gathering the minuscule solid particles scattered in a liquid.

Wastewater is treated with chemical coagulants like Al2(SO4)3 (also known as alum) or Fe2(SO4)3 to increase the attraction of the tiny particles, causing them to coalesce into bigger particles known as flocs.

- The flocculation process is improved by a chemical flocculent, typically a polyelectrolyte, which binds particles together to produce larger flocs that settle out more quickly.

- Gentle mixing encourages particle collisions, which aids in flocculation.

Secondary Treatment Level

Methods: This level makes use of both biological and chemical processes.

Removing or lowering the concentration of organic and inorganic compounds is a biological unit process. There are numerous biological treatment methods, but they are all centred on

microorganisms, mainly bacteria.

Aerobic Processes

In the presence of air, aerobic treatment activities occur (oxygen), uses the microorganisms (aerobes) that digest organic pollutants, converting them to carbon dioxide, water, and biomass, using molecular or free oxygen.

Tertiary/Advanced Treatment

Final cleaning procedure to raise the quality of wastewater before it is utilized again, recycled, or released into the environment.

Mechanism: Removes any leftover inorganic chemicals, including phosphorus and nitrogen. At this step, bacteria, viruses, and parasites that are hazardous to public health are also eliminated.

Methods:

Alum: Used to aid in further phosphorus particle removal and amalgamate the remaining solids for straightforward filter removal.

By eliminating bacteria, viruses, and parasites found in treated wastewater, the chlorine contact tank sterilizes tertiary treated wastewater. Just before it is released, sodium bisulphate is added to eliminate any remaining chlorine.

ETP Plant Operation

- Screening chamber

To prevent abrasion of mechanical equipment and clogging of the hydraulic system, remove relatively big solids.

- Collection tank

The effluent water from the screening chamber is collected, stored, and then pumped to the equalization tank by the collection tank.

- Equalization tank

The concentrations of the effluents are not constant, and the pH will occasionally change. Effluents are kept in the equalization tank for 8 to 12 hours, which causes a uniform mixing of effluents and aids in neutralization. It reduces shock loading on the treatment system that comes after. Additionally, constant mixing prevents sediments from accumulating in the equalization tank. Lowers SS and TSS.

- Flash mixer:

The effluents were given coagulants:

- Lime: (800–1000 ppm) To raise pH levels to 8–9

- Alum: (200-300 ppm) For colour removal

- To settle the suspended materials and minimise SS and TSS, add poly electrolyte (0.2 ppm).

When the aforementioned chemicals are added and mixed quickly and effectively, flocculates can combine uniformly to form micro flocs.

- Clarriflocculator:

The stirrer continuously stirs the water inside the clarriflocculator. Water that has overflowed is transported to the aeration tank. Flocculation produces slow mixing that results in the production of macro flocs, which eventually settle down in the clarifier zone. The solid particles are settled down, collected separately, and dried; this minimises SS and TSS. the settled solids( primary sludge) are pumped into the sludge drying beds

- Aeration tank:

A thin layer of water is carried across the various configurations in the form of a staircase. DAP and urea have been administered. The oxygen is dissolved into the water through direct contact with the air. Water’s BOD and COD readings are decreased by up to 90%.

- Clarifier:

The biological sludge is collected by the clarifier. The water that overflowed is referred to as effluent and dumped. The output water quality is examined to ensure that it falls within the permitted range specified in the Bureau of Indian Standards’ guidelines. The cleaned water is released into the environment, river water, arid area, etc. through pipes.

- Sludge thickener:

The inlet water consists of 60% water + 40% solids. The effluent is passed through the centrifuge. Due to centrifugal action, the solids and liquids are separated. The sludge thickener reduces the water content in the effluent to 40% water + 60% solids. The effluent is then reprocessed, and the sludge collected at the bottom.

- Drying beds:

Primary and secondary sludge is dried on the drying beds to reduce the water content.

Areas We Covered

Effluent Treatment Plant in Kakinada

Effluent Treatment Plant in Hyderabad

Effluent Treatment Plant in Coimbatore

Effluent Treatment Plant in Bangalore