Sequential Batch Reactor

Introduction to Sequencing Batch Reactors

Sequencing batch reactors (SBR) or sequential batch reactors is a technology designed to treat waste water. SBR varies from other technologies and wins through its unique way of using one tank for 5 steps thus proving effective in space utilization as compared to other conventional technologies. It is a batch process with 5 functions in a single tank.

Oxygen is bubbled through the wastewater to reduce the organic matter measured as biochemical oxygen demand (BOD) and chemical oxygen demand (COD). The treated effluent may be suitable for discharge to surface water such as land and gardening. This water could be further used for other applications by using a combination of other technologies based on the water inlet quality like using Reverse Osmosis after SBR to get clear water suitable for a number of process applications.

Process Description of Sewage Treatment Plan

Screening

Access chamber is to be provided at a separate unit and raw sewage is collected there. The sewage is passed through the screen provided at the inlet. To prevent damage to pumps and clogging of pipes, raw wastewater passes through mechanically raked bar screens to remove large debris, rags, plastics, sticks, and cans etc.

Oil and Grease Chamber:

After passing through the screen chamber, sewage reaches the Oil and Grease chamber where all the floating material like oil & grease are separated to protect biological activities in the aeration tank.

Equalization/collection Tank

This tank shall collect the waste water from the oil & grease tanks at various intervals to homogenize it properly.

Technical Features

The wastewater treatment technology should have mentioned below features.

✔ Only aerobic i.e. in presence of oxygen.

✔ Compact type – The main process units shall be placed as close as possible & land required is minimum.

✔ No generation of foul gasses like methane, H2S in the treatment process.

✔ Least operating cost

✔ Least chemical requirement in the process.

✔ Plant should be fully automatic and the PLC (Programmable Logic Controller) panel should be

considered to avoid complications & requirements of highly educated operators.

✔ The treatment process should be self-sustaining.

The Process of Sequential Batch Reactor:

The sequencing batch reactor (SBR) process is a sequential-suspended growth process where all major steps occur in the same tank in sequential order. SBRs are a variation of the activated‐sludge process. They differ from activated‐sludge processes as they combine all the treatment steps and processes into a single basin or tank, whereas conventional facilities rely on multiple basins.

Basic Treatment Process

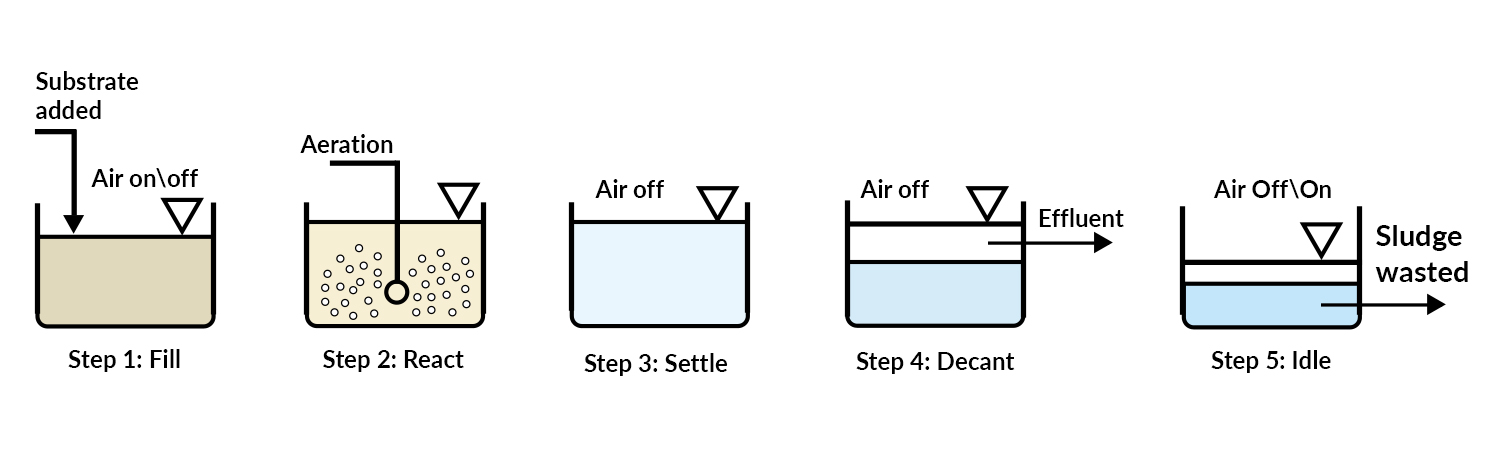

The principle of an SBR is based on a fill‐and‐draw, which consists of five steps – fill, react, settle, decant, and idle. These steps are altered for different operational applications.

Fill: In this step, the basin receives influent wastewater. The influent brings food to the microbes in the activated sludge, creating an environment for the process of biochemical reactions.

React: This step allows for further reduction or “polishing” of wastewater parameters. When the mechanical mixing and aeration units are on, no waste water enters the basin. As there is no additional volume and organic loadings, the rate of organic removal increases greatly.

Settle: In this step, the activated sludge is allowed to settle under quiescent conditions – no flow enters the basin and no aeration and mixing takes place. The activated sludge settles as a flocculent mass, forming a distinctive interface with the clear supernatant.

Decant: In this step, a decanter is used to remove the clear supernatant effluent.

Idle: This step is between the decant and the fill phases. During this phase, a small amount of activated sludge at the bottom of the SBR basin is pumped out through this process called wasting.

Disinfection

Before the final sewage is released into the receiving waters, it may be disinfected to reduce the disease-causing microorganisms that are left. The most effective process is chlorination to disinfect.

Pressure Sand Filter

The process of passing the water through beds of sand or other granular materials is known as sand filtration. The water to be treated is passed under high pressure. These filters essentially consist of a thick layer of sand and the water is allowed to pass with pressure through it. This process removes turbidity, suspended particles, colour and odour that are present in wastewater.

Clear Water Tank

In this tank, clear water is subjected to tertiary treatment for further treatment of Sewage. It collects clear water from the secondary tube settler from where it comes through gravity. After that, it is passed through a sand filter and activated carbon filter.

Filtration/Adsorption

The clear influent from the above tank is passed through a series of Filtration, sand and Carbon filter columns which act as coarse and fine filtration / removal of the residual and undesired suspended impurities.

Areas We Covered

Sequential Batch Reactor Plant in Kakinada

Sequential Batch Reactor Plant in Hyderabad

Sequential Batch Reactor Plant in Vizag

Sequential Batch Reactor Plant in Coimbatore

Sequential Batch Reactor Plant in Bangalore